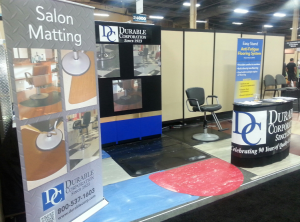

Durable Corporation is exhibiting July 13-15th at Cosmoprof North America. Held in Las Vegas, Nevada, Cosmoprof is the largest beauty industry trade show in North America. During the show, we’ll visit with dealers and distributors interested in learning more about Durable’s Grand-Stand Deluxe Beauty and Barber Mat and our new, Grand-Stand Vinyl Salon Mat. Grand-Stand Vinyl is available in four attractive colors and features a thick sponge base for all day comfort.

In addition to these portable salon mat offerings, we’ll also showcase our patented Easy Stand Anti-Fatigue Flooring System. Easy Stand is a permanently installed anti-fatigue mat that seamlessly blends with adjacent flooring. Whether your application requires individual chair mats, or an anti-fatigue flooring system designed for a larger, continuous work area, Durable Corporation offers long-lasting salon mat solutions in a wide range of colors and sizes to meet your specific needs.

If you are planning to attend Cosmoprof North America, please stop by and visit with us in Booth D3121. See you in Vegas!

Dealer Log In

Dealer Log In

1.800.537.1603

1.800.537.1603